Abtrex Industries Incorporated was founded in 1969. The company specializes in rubber lining and other abrasion and corrosion-resistant protective linings.

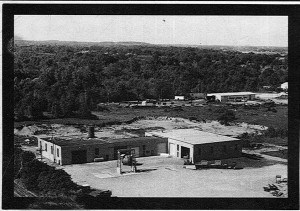

As a result of strategic planning and advancement, Abtrex Industries now serves clients from multiple bases of operation and provides world-class solutions around the globe.

Through years of dedicated service, Abtrex Industries has tackled some of the most difficult demands of the manufacturing industry. Our crews are professionally trained to tackle tank linings, tank inspections, tank coatings, as well as on-site fabrications and repairs.

Want to learn more about Abtrex? Contact us today.